How do mechanical presses work? Complete explanation of the process and its components

How do presses work? Mechanical presses are fundamental machines in the metallurgical and stamping industry. Their ability to transform rotary motion into controlled linear motion allows for high-precision cutting, punching, bending, and deep drawing operations. In this article, we explain in a clear and technical manner how mechanical presses work, what their main components are, and why they remain one of the most widely used technologies in industrial manufacturing.

What is a mechanical press?

A mechanical press is a machine that uses a flywheel, clutch and crankshaft system to generate vertical movement of the slide. This movement applies a controlled force to a die or tool, deforming the metal material according to the required operation.

Its operation is based on the accumulation of mechanical energy and its precise and repetitive release.

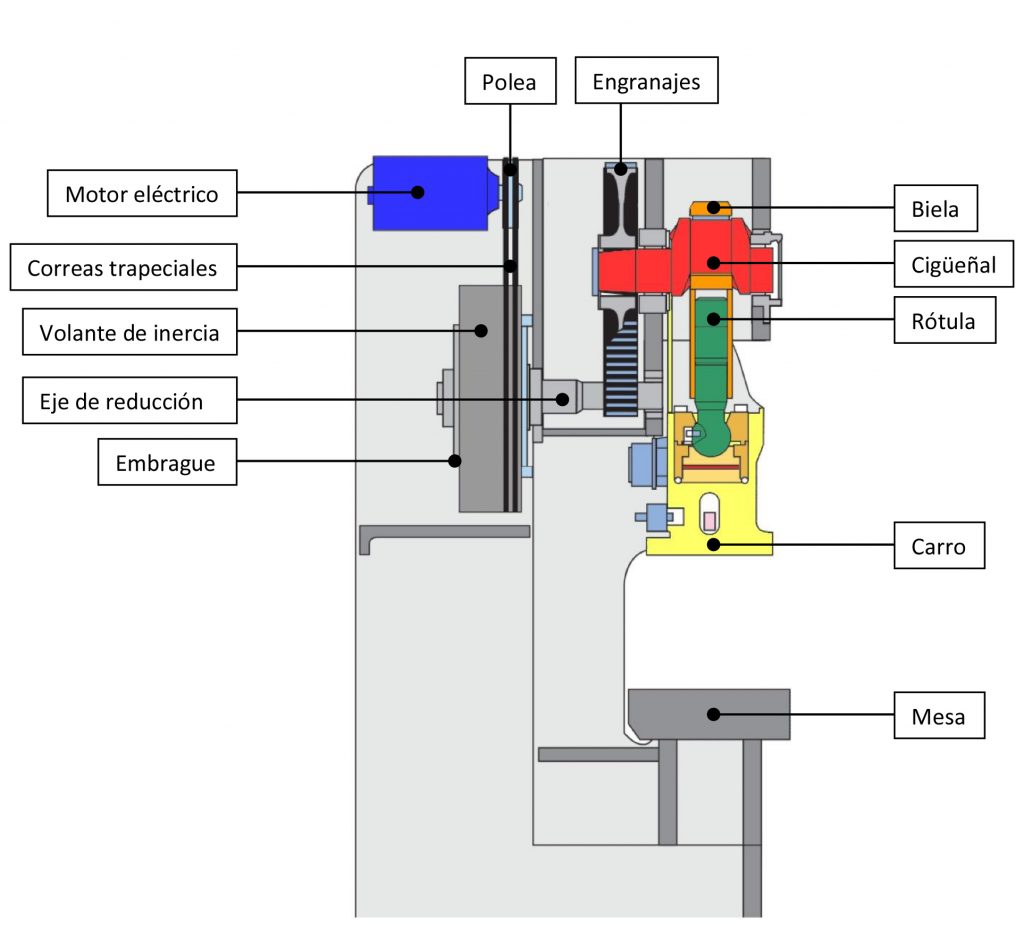

Main components of a mechanical press

To understand how it works, it is important to know the parts involved in the process:

1. Flywheel

It accumulates kinetic energy as it rotates at high speed. This provides sufficient power during the working cycle.

2. Clutch

Connect and disconnect the flywheel from the crankshaft. Control the start of the compression cycle.

3. Crankshaft

Converts rotary motion into linear motion. It is the heart of the mechanical system.

4. Connecting rod

Transmits the movement of the crankshaft to the slide valve.

5. Slider (or carriage)

Movable part that descends to perform the stamping operation.

6. Table or countertop

Fixed surface where the lower die is placed.

7. Motor

Provides the energy needed to turn the steering wheel.

How a mechanical press works, step by step

The operation of a mechanical press can be divided into several phases:

1. Energy accumulation

The motor turns the flywheel, which stores kinetic energy..

2. Clutch engagement

The operator or the automatic system activates the clutch, connecting the flywheel to the crankshaft.

3. Crankshaft movement

The crankshaft transforms the rotation into a vertical movement.

4. Slide descent

The slide descends with controlled force towards the die.

5. Material deformation

The material is cut, bent or embossed depending on the tool installed.

6. Return

The crankshaft completes its rotation and the slide returns to its initial position.

This cycle can be repeated hundreds of times per minute in high-speed presses.

Types of mechanical presses and how they work

Eccentric presses

The most common. They use an eccentric crankshaft to generate movement.

Double-column presses

Designed for heavy-duty work and high stability.

C-frame presses

More compact, ideal for lower tonnage operations.

Advantages of mechanical presses

- High production speed

- High repeatability

- Low maintenance cost

- Precision in cutting and punching operations

- Simple integration into automatic lines

Industrial applications

Mechanical presses are used in:

- Automotive

- Household appliances

- Metallurgical

- Component manufacturing

- Stamping of small and medium-sized parts

Recommended maintenance for mechanical presses

Proper maintenance is key to preventing breakdowns and extending the machine’s service life. The most important tasks include:

- Clutch and brake inspection

- Checking the crankshaft and connecting rod

- Adjusting slack in the slide

- System lubrication

- Verification of alignments

- Inspection for cracks or wear

Mechanical presses are essential machines in modern industry thanks to their speed, precision and reliability. Understanding how they work helps to optimise production, improve safety and reduce the risk of breakdowns. With proper maintenance, these machines can provide decades of efficient service.