Our clients report material savings of 20%–30%!

More information

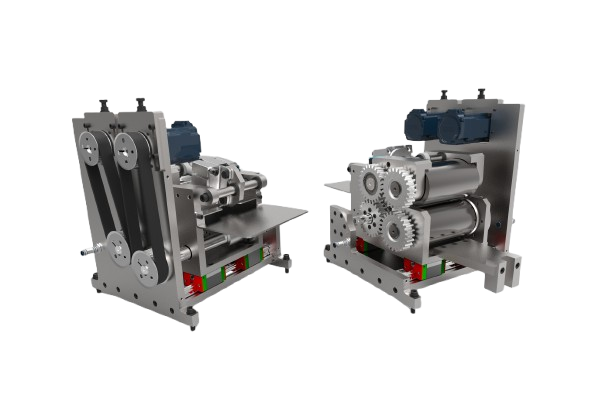

ZigZag Servo Feeder – Platarg 612

General Description

The ZigZag Servo Feeder for Platarg 612 is engineered for maximum precision and efficiency in sheet feeding operations. It features two high-performance servo motors: one for lateral movement and one for roller feed. The system operates on precision linear guides and uses inductive sensors to guarantee accuracy in every cycle.

Roller clamping and unclamping is managed by a pneumatic system with permanently meshed gears, preventing step loss. Control is handled via a Siemens 1211C DC/DC/DC CPU (6DI/4DO/2AI) and a Siemens SIMATIC HMI KTP700 Basic panel for easy operation and parameter adjustment.

Main Features

| Feature | Specification |

|---|---|

| ZigZag Movement | 74 mm |

| Supported Sheet | Max. Width: 130 mm Max. Thickness: 3 mm |

| Feed Accuracy (per 100 mm) | <0.1 mm |

| Lateral Movement Accuracy | ±0.04 mm |

| Servo Motors | Siemens 1FL2/3AC 200V & SINAMICS S200 PN Driver, 1/3 AC 200V 0.2 kW |

| Max Speed (strokes/min, ZigZag) | 100 strokes/min with 75 mm disc |

Note: Working speed depends on the material, manufacturing process, and press electrical response. The feeder can be customized for specific customer requirements if sufficient design information is provided.

Technical Specifications

| Component | Specification |

|---|---|

| Structure | High-strength structural aluminum |

| Rollers | F-125 treated steel |

| Shafts & Mechanical Drives | High-quality steel with verified strength |

| Gears | F-155 carburized |

| Commercial References | Leading brands (SKF, THK) |